Our Products

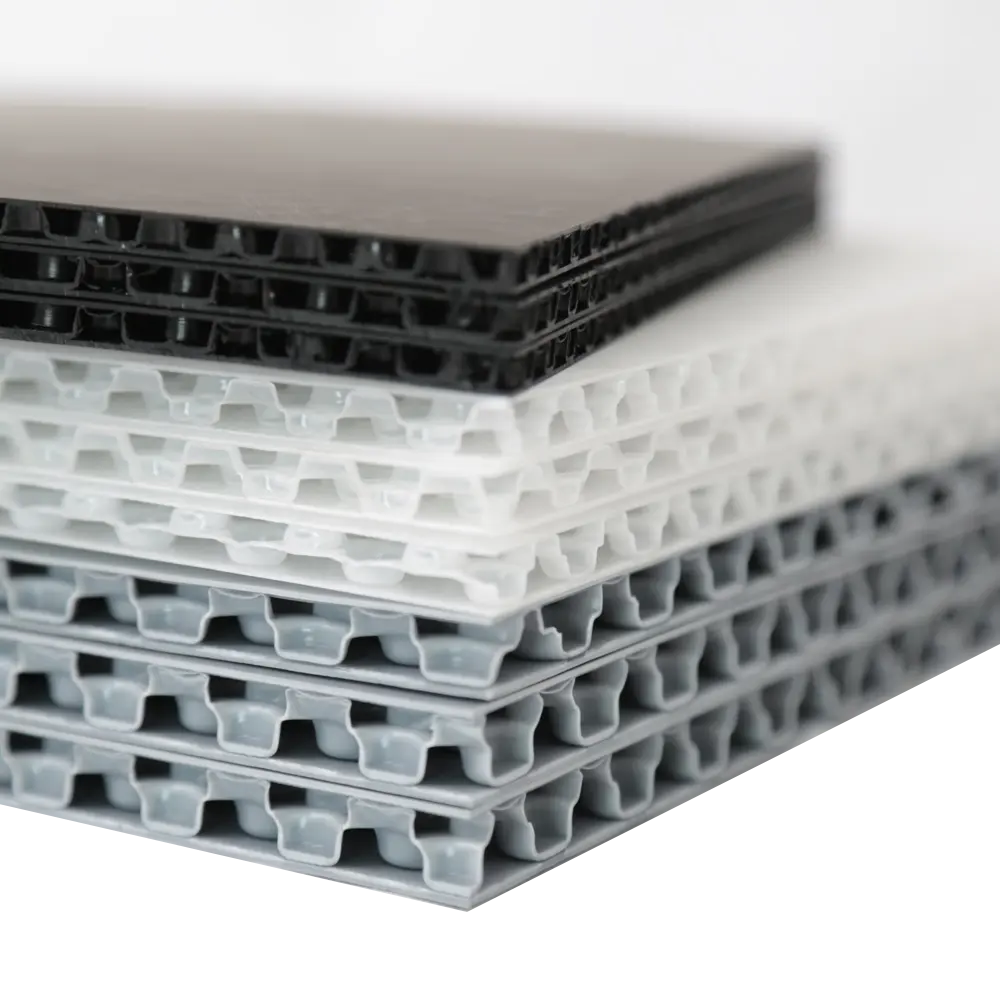

PP Hollow Sheets

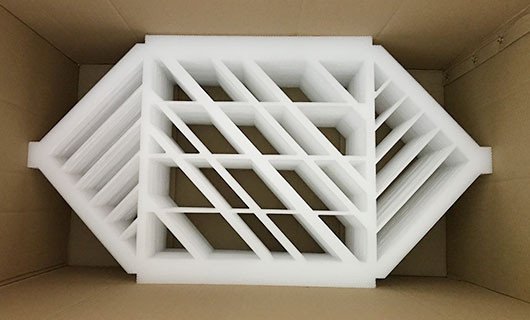

PP Corrugated Dividers

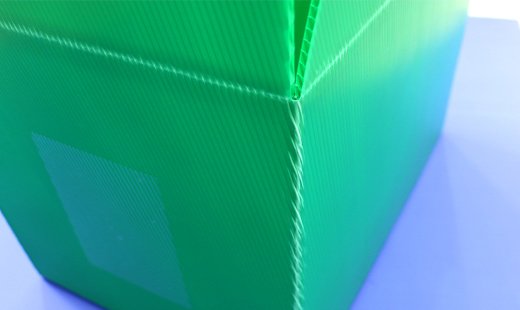

Hollow Sheet Containers

PP Honeycomb Panels

PP Corrugated Containers Honeycomb Core

Collapsible PP Honeycomb Containers

Enhanced Performance

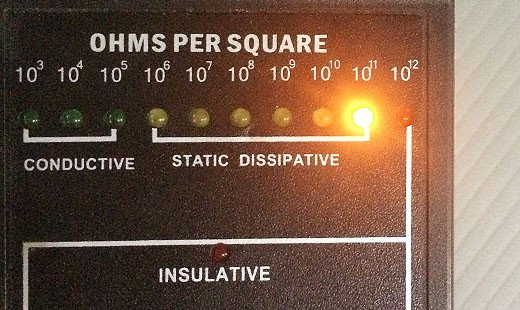

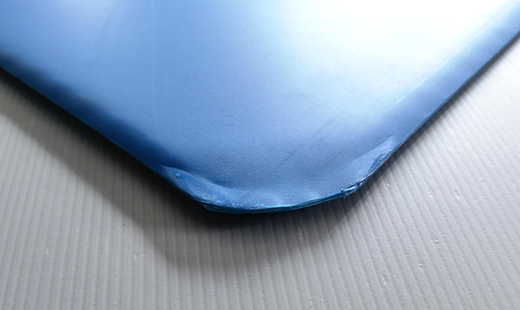

In addition to our standard polypropylene corrugated sheets, we also offer performance-enhanced variants tailored to specific needs. These enhanced polypropylene corrugated sheets include options for anti-static sheets, high dyne value sheets, and flame-retardant sheets.

(Anti-Static Treatment)

(High Dyne Value Treatment)

(Flame-Retardant Treatment)

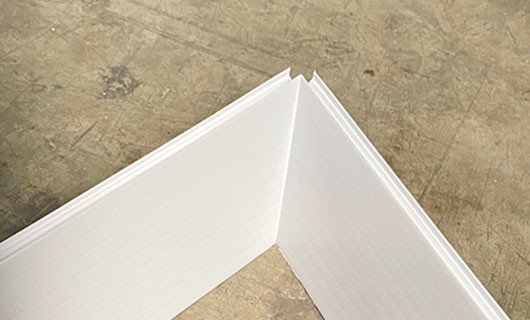

Sealing Types

Edge Sealing with PP Rod PP

Edge Sealing by Hot Melting

Screen printing, digital printing, and laser marking, provide versatile printing and marking solutions for polypropylene corrugated sheets, ensuring high-quality, vivid graphics for promotional materials and precise, permanent markings for detailed designs.

Types of Processing

At NewPlast, we offer more than just plastic polypropylene corrugated sheets. We provide a wide range of processing services tailored to advertising, packaging, logistics, and construction industries. Our services include:

● Edge trimming, die-cutting, and CNC engraving, enable precise customization of polypropylene corrugated sheets, ensuring they are perfectly squared, shaped to specific dimensions, and intricately designed to meet various application needs.

Cutting Service

Edge Trimming

Automatic Die-Cutting

CNC Engraving

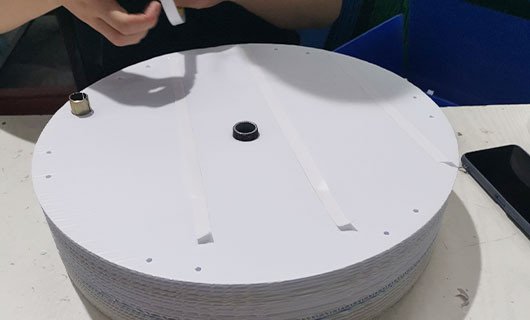

Die Cutting includes cutting sheets to specific sizes or shapes, half-cutting for easy folding, and creating crease lines for added flexibility in assembly.

。

Full Cut

Half Cut

Crease Line

Printing Service

Screen printing, digital printing, and laser marking, provide versatile printing and marking solutions for polypropylene corrugated sheets, ensuring high-quality, vivid graphics for promotional materials and precise, permanent markings for detailed designs.

Manual Screen Printing

Machine Screen Printing

Laser Marking

Composite Process

Lamination/Adhesion techniques allow for the attachment of materials like tape, velcro, EPE foam, EVA foam, and fabric to polypropylene corrugated sheets, providing enhanced protection, padding, and customization for packaging and other specific applications

EPE Foam Laminate

Tape Laminate

Fabric & EVA Laminate

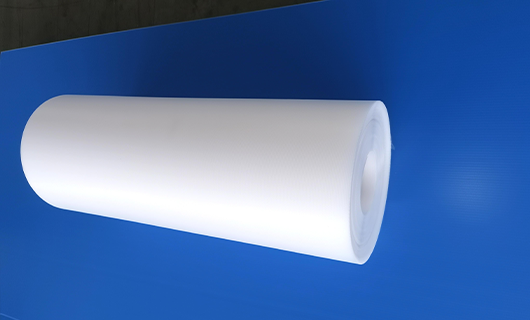

Versatile Packaging

We offer a wide range of packaging solutions tailored to meet different customer requirements. With extensive experience collaborating with well-known international brands, we ensure professional, secure, and efficient packaging. In addition to standard methods, we also provide roll-packaging options to accommodate large-volume or special-format orders.

Roll Packaging

Standard Sheet with Edge Protection

Learn more from our FAQ

Not sure which material is right for your purpose? Whether we can cut to custom size? Ask for quotation? Ask for MOQ?

We are a manufacturer. Despite “Trading Ltd.” in our name, we operate a 20,000㎡ factory with 7,500-ton annual output, holding 22 patents and employing 9 engineers.

Of course we can.

NewPlast processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

T/T, L/C, PayPal, Western Union payment are available.

Usually 15 to 20 days.

The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

get in touch

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply as fast as possible.

Visit our office

6 Huaye Avenue, Dongbang Town, Changshu, Suzhou, Jiangsu Province, China